Behind the Scenes Series | Nautical Picnic Table | Installment 1 of 3

Today we’re delving into our first ever “behind the scenes” series and taking you through the journey of this monster of a project. With so many moving parts, we’re going to break it down from concept to completion.

THE VISION

Client’s Must-Haves

- Picnic Style Tables for shore home to accommodate about 20 people – must be sturdy and able to take a beating

- Base of table needs to be high enough to fit tall people

- Nautical Themed

- Family loves playing games, so oversized inlayed tile gameboards of choice

- Drawers to keep game pieces in when not in use

- Benches wide enough to accommodate heavier people, must tuck in under table when not in use and be sturdy enough for little kids to be able to stand on without tipping over

- No metal hardware that will rust from the

salty air

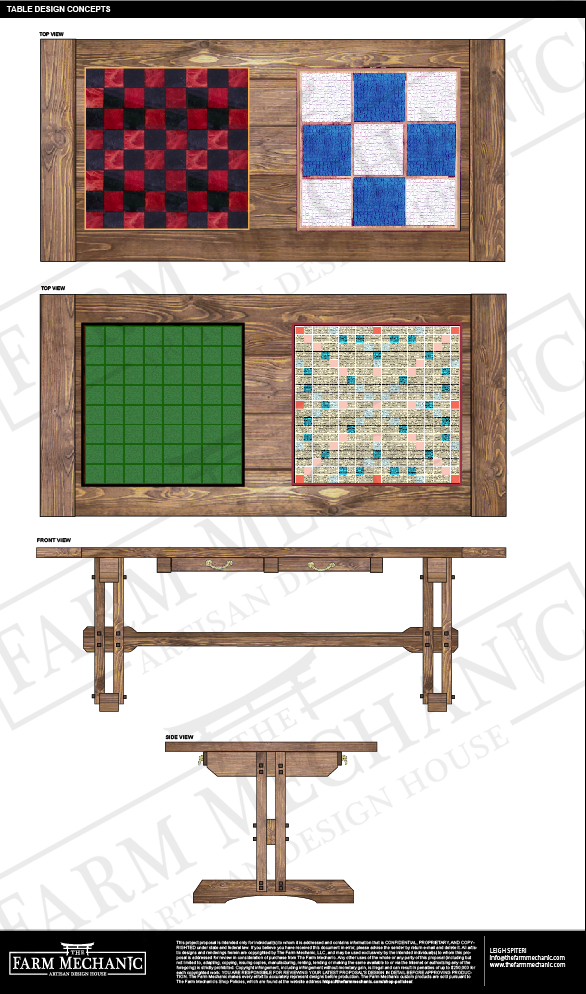

THE

DESIGN

THE FABRICATION

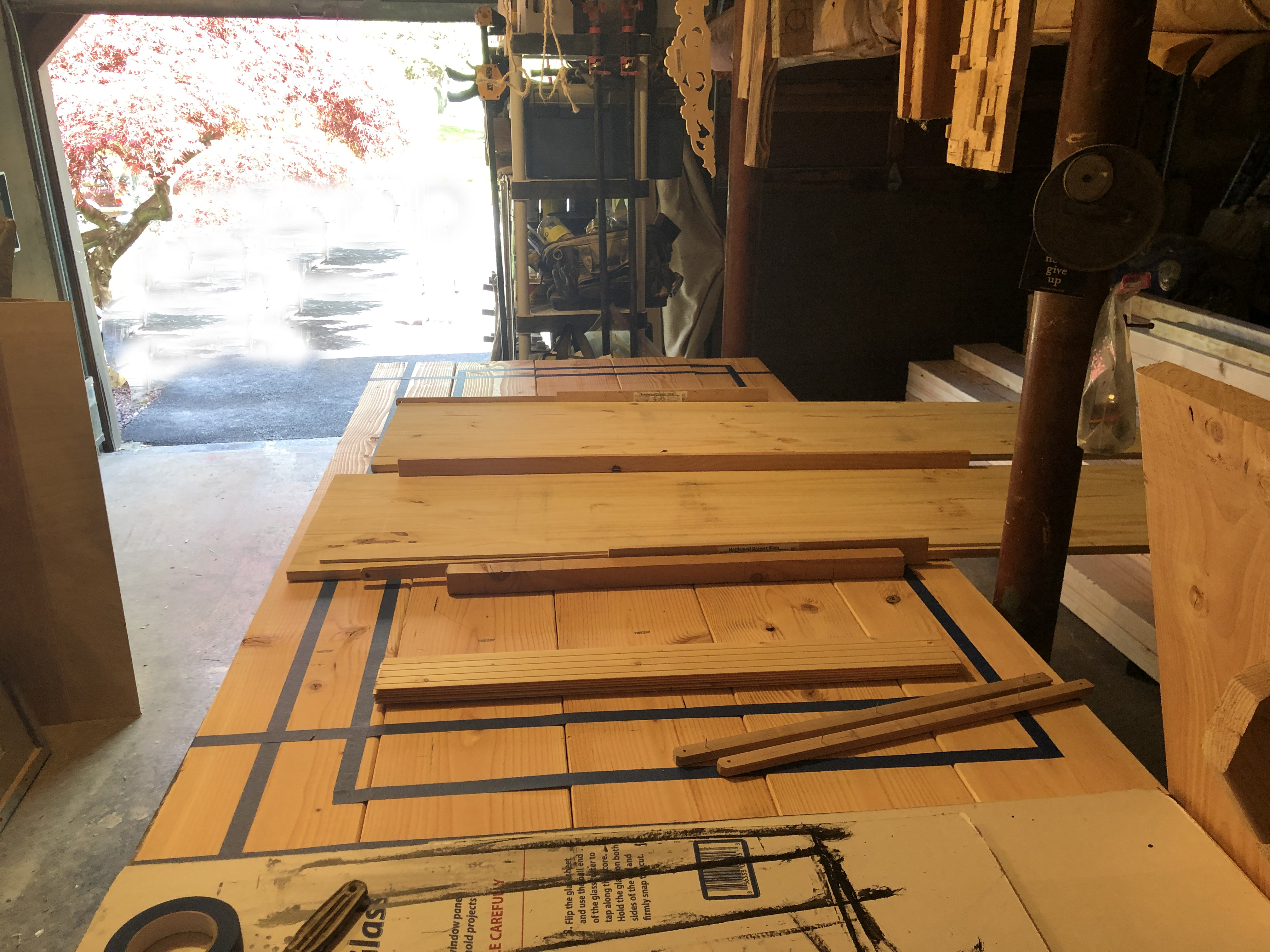

When the final design is approved, we start to breathe life into the project

off the paper -moving from concept to reality which begins with simultaneously

selecting each piece of lumber and sourcing the tile for the board games.

Once the lumber is in our shop, it’s time to start selecting which pieces will go together to serve as the table tops and bench tops – we take a lot of time to ensure the prettiest grain is featured which really adds to the “wow” factor during the reveal. We also figure out the placement of the board games at this point.

Once this is established, we biscuit join the lumber together which helps keep things aligned and provide some extra strength.

We repeated this process to create the two tabletops and eight bench tops and put them off to cure.

A Little About Our

Thought Process

Once we take into consideration the clients must-haves, we apply our design

philosophy that is heavily influenced by Frank Lloyd Wright and Japanese

Architecture. We thought about the main components of this project as a pier. In

keeping with Frank Lloyd Wright’s philosophy of strong design, while working in

harmony with the environment – we wanted the table to look like a floating pier

when you walk by (you’ll see this when it all comes together later on). The

table and bench tops represent the tops of a pier. The legs, made of four

separate pieces, represent beautiful strong pillars to allow air flow. The

sturdy, oversized feet rest on two points. The four pillars are cradled into

the feet providing stability. Each underskirt acts as the connector piece

between tops and bases and also provides space for the rail system for the

hidden drawers beneath the tables.

As our tops were curing it was time to create the table and bench base components which included center brace supports, the underskirts, legs and feet.

The Center Brace Supports

As you see in the rendering, this is where the Nautical

theme really shines. We decided to create the center brace supports of the

tables and benches in the shape of an oar. After studying various oar designs

and deciding on one, we needed to make sure the oar was proportioned properly

to fit the wide expanse of the tables while maintaining the look of an actual

oar and be strong enough to support the table properly. We then scaled down

this design for the larger benches and scaled down even further for the smaller

end benches.

The Underskirt

The underskirts for the tables and benches play a crucial role in the

design. The skirt needs to align and marry the table tops and the bench tops to

the bases, which was achieved through a series of painstakingly intricate cuts

in order to achieve a seamless and sturdy fit. We needed to also pay close

attention to ensure that the skirt didn’t interfere with varying knee heights. On

the tables, the skirt also served as a rail system for the four hidden drawers. More

about the drawers next week.

Legs and Feet

The benches required a total of 64 individual legs and the tables required 8

large legs. That’s A LOT of legs! LOL Each leg was individually cut, carved, shaped

and refined. Like everything else that is done in the way of Japanese

aesthetics each and every piece has a function and everything has its place.

Each component works in relationship and harmony with one another. The benches

required 12 feet, while the tables required 4 monster sized feet. As you can

see, our designs are scalable. Each foot was cut, carved, shaped and refined to

cradle the legs. This was a very time-consuming part of the design, but so

essential because it adds stability, strength and beauty, oh so much beauty.

After all of the above is completed, it’s finally time to assemble the bases. Further adjustments were made at this point to ensure that everything fit like a glove. First the skirts were secured to the tables and bench tops. We designed a base key that is also secured to the tops which was another tool to keep everything aligned precisely.

Once the base keys were secured, the legs were inserted and secured into the key. Now that the beautiful pillars are in place, the feet are then inserted and secured into the legs. We repeat the process for all 8 benches and finish with inserting the center brace. The process for the table bases were slightly different for two reasons. First reason is we installed the rail system for the hidden drawers. The other difference is the table tops separate from their bases to allow for easier mobility and movement for transport.

We then do extensive mudding, sanding and quality assurance.

Stay tuned...next week, in part 2, we'll be covering the hidden drawers, the monster oversized board games and the custom game pieces.

Let us know what you think! Drop a comment, send us an email – we’d love to hear from you.

Sign up for our newsletter to get it straight to your inbox! We sometimes even share a promo code.